Nigeria Sinotruk Local Sales Center 2025 Howo New Model

Nigeria Sinotruk Local Sales Center 2025 Howo New Model Nigeria Sinotruk Local Sales Center 2025 Howo New Model

Nigeria Sinotruk Local Sales Center 2025 Howo New ModelFrom structural layout to mechanical systems, every component is designed to deliver stable performance while minimizing downtime and long-term servicing costs. This engineering philosophy makes the cement tanker a dependable transport solution for operators working under demanding conditions across Nigeria.

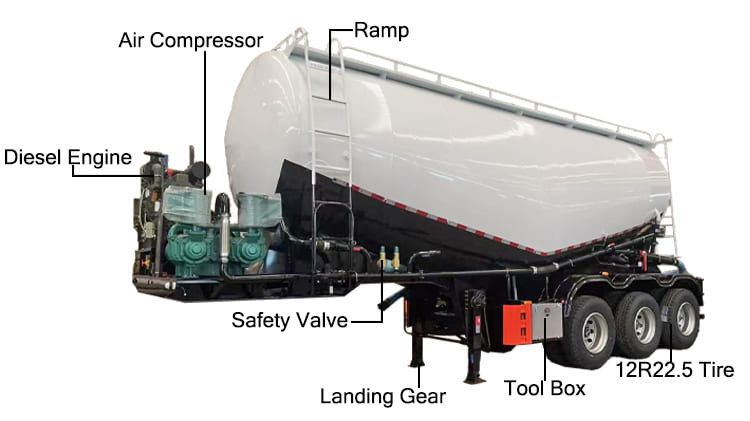

Tanker body material: 5mm high strength steel

Volume: 42CBM

Axles: 3 axles, 13ton

Tire: 12 units, 12R22.5

Voltage: 24V

Compressor: 12m³ double cylinder air compressor

Compressor Brand: BOHAI brand

Diesel Engine: WEICHAI brand

Suspension: heavy-duty mechanical suspension

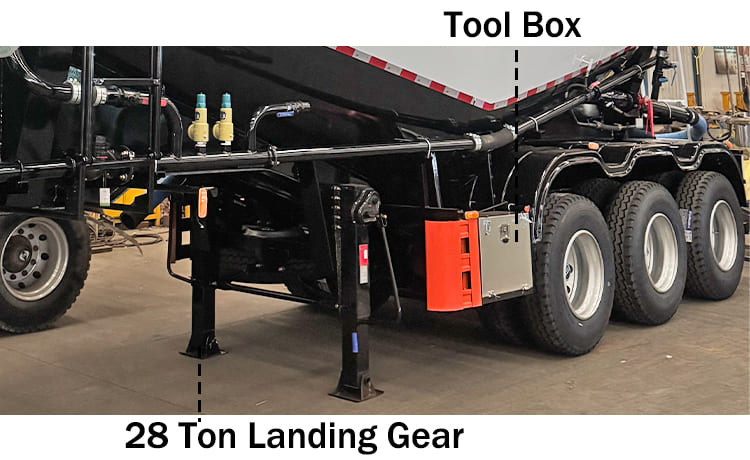

Landing gear: 28 ton

Lamp: LED lamp with anti-theft design

Surface treatment plays a crucial role in extending service life and preserving appearance. To achieve this, each cement tanker is finished using an advanced powder-spray coating process rather than conventional liquid paint. Although this method involves higher initial production costs, it offers significant long-term advantages in corrosion resistance and surface durability.

Under the hot, humid, and dusty climate commonly experienced in Nigeria, the powder-coated surface maintains its color, texture, and protective properties for many years. This reduces the need for frequent repainting and helps protect the steel structure from oxidation, ultimately lowering lifecycle maintenance costs and preserving asset value—an important factor when evaluating overall cement tanker price.

Operational safety during unloading is addressed through a carefully designed pressure control system. Each cement tanker for sale is equipped with a dual safety valve arrangement that evenly distributes internal air pressure between two independent valves. This balanced configuration reduces localized wear and extends component lifespan.

During discharge, when pressure fluctuations occur, both valves respond simultaneously, preventing sudden pressure spikes and maintaining stable internal conditions. This safety-oriented design protects both the tank structure and operators, particularly during high-frequency loading and unloading cycles common in bulk material transport across Nigeria.

Powering the pneumatic unloading system is a reliable diesel engine platform, widely recognized for stable output, efficient fuel usage, and strong torque characteristics. The engine supplies continuous airflow to the pneumatic system, ensuring smooth and complete material discharge.

For transport companies comparing cement tanker price and long-term operating efficiency, this balance of performance and fuel economy is especially valuable. On routes that combine paved highways with rough inland roads throughout Nigeria, consistent engine performance helps reduce fuel costs while maintaining dependable unloading efficiency.

Stability during parking and loading is supported by a heavy-duty landing gear system. Every cement tanker for sale is fitted with landing gear capable of supporting loads of up to 28 tons. Its wide, reinforced base improves ground contact and balance on uneven or soft surfaces.

The straightforward mechanical design allows operators to raise or lower the landing gear quickly without specialized tools, improving daily usability and reducing labor intensity—an advantage for fleets operating in varied environments across Nigeria.

Axle and suspension design further enhance long-term reliability. The cement tanker adopts a tri-axle configuration that distributes weight evenly across the frame and tires, reducing concentrated stress points that could lead to deformation or premature wear.

Heavy-duty 13-ton axles provide excellent vibration absorption and stability, ensuring controlled handling even on unpaved or uneven roads. This setup improves road safety, extends tire lifespan, and preserves structural integrity, all of which positively influence the overall cement tanker price over its service life.

Quality assurance is an essential part of production. Every cement tanker for sale undergoes comprehensive testing before delivery. High-pressure tests are conducted to confirm there are no cracks, leaks, or weak points in the tank structure. These are followed by non-destructive ultrasonic and flaw detection inspections to identify any internal imperfections.

These strict inspections ensure airtight sealing, structural safety, and long-term durability, reflecting the standards expected from professional manufacturers and reinforcing buyer confidence when assessing cement tanker price versus performance.

Before shipment, each cement tanker receives a multi-layer protective treatment. Anti-corrosion wax is applied to exposed surfaces, and the unit is securely wrapped with a waterproof tarpaulin. This double-layer protection shields the tanker from salt air, moisture, and airborne contaminants during sea transport, ensuring it arrives ready for immediate operation without additional preparation.

Add: PLOT 3, OBA, AKRAN AVENUE, IKEJA, LAGOS